In the realm of fashion accessories, custom leather bags have always been a symbol of elegance and individuality. The key to creating exceptional custom leather bags lies in a well-thought-out and rigorous approach to custom leather bag production. As a professional custom leather bag manufacturer with a state-of-the-art leather bag factory in China, we take great pride in our comprehensive process that ensures every bag we produce meets the highest standards of quality and craftsmanship in custom leather bag production.

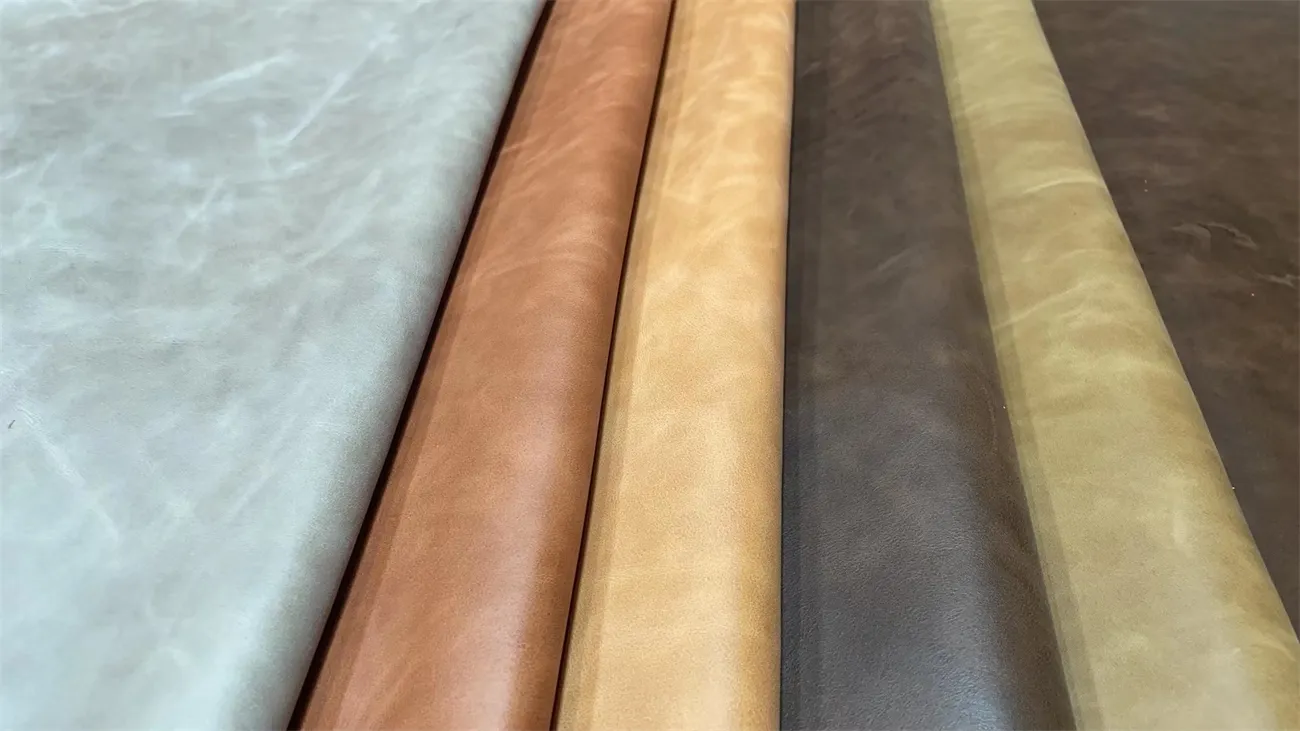

Material selection serves as the cornerstone of superior custom leather bag production. We recognize that the quality of leather directly influences the final product in custom leather bag production, so we have established strict criteria for sourcing raw materials. Our expert team travels to renowned leather-producing regions worldwide to procure top-grade hides, meticulously inspecting each piece for texture, thickness, and durability—all critical for successful custom leather bag production.

Different leather materials offer distinct characteristics, and we tailor our selections to meet specific custom order requirements in custom leather bag production. Full-grain leather, with its natural markings and rich texture, caters to clients seeking a vintage and authentic aesthetic in their custom leather bags, a key goal in our custom leather bag production. Conversely, top-grain leather—smoother and more uniform—suits those preferring a sleek, mo dern style, ensuring versatility in custom leather bag production. This careful material matching lays a solid groundwork for outstanding custom leather bag production.

After material selection, the design and prototyping phase emerges as a crucial step in custom leather bag production. Our design team collaborates closely with clients to understand their vision, preferences, and functional needs, translating these ideas into detailed sketches before creating prototypes using selected leather materials—all integral to custom leather bag production. This phase ensures that client expectations are aligned with production capabilities in custom leather bag production.

Prototyping allows clients to visualize the final product and request adjustments before mass production begins, a vital practice in custom leather bag production. During this stage, we test bag functionality, ensuring optimal positioning of pockets, zippers, and straps for convenience—details that define excellence in custom leather bag production. This iterative process guarantees the design meets all expectations, paving the way for a seamless mass manufacturing process in custom leather bag production.

Once designs are finalized, we transition to mass manufacturing, where advanced mass production lines and automated equipment play a vital role in custom leather bag production. Our leather bag factory in China is equipped with cutting-edge machinery that streamlines production while maintaining precision and consistency—hallmarks of our custom leather bag production. This technology-driven approach ensures efficiency without compromising quality in custom leather bag production.

The first step in mass manufacturing is cutting leather into required patterns, a foundational task in custom leather bag production. Guided by computer-aided design (CAD) software, our automated cutting machines ensure utmost accuracy, minimizing waste and ensuring perfect fit during assembly—critical for maintaining standards in custom leather bag production. This precision is essential for upholding quality in custom leather bag production.

Following cutting, the assembly phase begins, with skilled craftsmen collaborating with automated sewing machines to bring bags to life in custom leather bag production. Automated machines handle repetitive tasks with speed and precision, ensuring strong, even stitches, while craftsmen focus on intricate details like hardware attachment, lining addition, and edge finishing—all key elements of custom leather bag production. Each step is monitored to meet strict quality standards, as we believe this blend of technology and craftsmanship is key to efficient, high-quality custom leather bag production.

Quality control is an integral part of our custom leather bag production process, running through every stage from material selection to final inspection in custom leather bag production. Before entering our factory, leather undergoes rigorous testing for strength, flexibility, and wear resistance—essential checks for custom leather bag production. This commitment to quality ensures that every product meets our high standards in custom leather bag production.

During production, each bag is inspected at multiple checkpoints to verify secure stitching, proper hardware attachment, and flawless finishes—non-negotiable aspects of custom leather bag production. We also conduct real-world use simulations, testing strap and zipper durability to ensure longevity in custom leather bag production. Only after passing all checks are bags approved for delivery, ensuring clients receive custom leather bags that are both beautiful and built to last— the ultimate goal of custom leather bag production.

Beyond quality, we prioritize sustainability in custom leather bag production, integrating eco-friendly practices into every aspect of custom leather bag production. We partner with suppliers committed to ethical and environmentally friendly practices, minimizing waste by reusing and recycling leather scraps—key initiatives in responsible custom leather bag production. Our production processes are designed to reduce energy consumption and carbon footprint, allowing us to create high-quality products while contributing to a better planet through custom leather bag production.