Leather bags stand out for their durability, craftsmanship, and timeless style—but none of these qualities shine without the right hardware. For leather bag designers and teams focused on custom leather bag production, understanding bag hardware types is non-negotiable: the right zipper, clasp, or D-ring can turn a basic design into a functional, luxurious piece, while a poor choice can undermine durability and aesthetics. Whether you’re new to the industry and wondering how are leather bags made or a seasoned designer refining your custom line, breaking down key hardware components will help you make intentional choices that align with your brand and client needs.

Zippers are more than just closures—they’re essential to a bag’s usability, whether it’s a crossbody, tote, or satchel. In leather bag design, the type of zipper you choose directly impacts both function and style, making it a critical part of understanding bag hardware types.

Not all zippers work for leather:

Metal zippers: Made from brass, nickel, or aluminum, these are ideal for high-end custom leather bags. They’re durable, resist wear, and add a premium touch—perfect for luxury satchels or briefcases.

Nylon zippers: Lightweight and flexible, nylon zippers suit casual styles like backpacks or tote bags. They’re cost-effective but less suited for heavy-duty leather pieces.

Resin zippers: Sturdy and available in bold colors, resin zippers work for statement bags. They’re water-resistant, making them a good choice for weekend duffels.

In the production process, zippers are installed after the bag’s main body is stitched. For leather, this requires precision: leather’s thickness means zippers must be attached with reinforced stitching to avoid tearing. In custom leather bag production, clients often request specific zipper finishes (e.g., antique brass for a vintage look) to match their brand’s aesthetic—another reason why knowing zipper options is key to delivering tailored results.

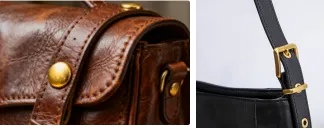

Clasps keep bags closed while adding visual interest. They’re a focal point for many designs, so choosing the right clasp is as much about style as it is about function—especially in custom leather bag production.

Turn-lock clasps: These feature a metal tab that twists into place, offering strong security. They’re a staple for structured bags like doctor’s bags or luxury handbags, as they exude elegance.

Push-lock clasps: Easy to open with one hand, push-lock clasps are great for everyday bags like crossbodies. They’re sleek and modern, making them popular for minimalist custom designs.

Toggle clasps: Made from leather or metal, toggle clasps use a bar that slides through a loop.

In custom work, clasps are often customized to match a client’s vision. For example, a brand focused on sustainability might request wooden toggle clasps, while a luxury label may opt for hand-polished brass turn-locks. When answering how are leather bags made, we often note that clasps are installed last—after the bag’s structure is complete—to ensure they align perfectly with the design’s proportions.

D-Rings are small but mighty: their simple, D-shaped design makes them one of the most versatile bag hardware types, used for everything from attaching straps to adding decorative accents.

Strap attachment: The most common use—D-Rings are sewn into the top or sides of bags to connect shoulder straps or crossbody straps. They allow straps to move freely, improving comfort.

Accessory loops: Small D-Rings inside or outside the bag can hold keychains, coin pouches, or even water bottle holders, adding practicality to custom designs.

Decorative details: Oversized or colored D-Rings can act as statement pieces, especially on minimalist bags where hardware is the focal point.

Beyond zippers, clasps, and D-Rings, other hardware pieces complete a leather bag’s design and functionality. These often go overlooked but are critical to both how are leather bags made and delivering high-quality custom work.

Rivets are small metal fasteners used to strengthen high-stress areas, like where straps meet the bag body. Eyelets—small, punched holes lined with metal—are used for drawstring bags or to attach charms. In custom leather bag production, we use brass or stainless steel rivets to avoid rust, ensuring the bag holds up to daily use.

Magnetic snaps use hidden magnets to keep bags closed. They’re ideal for tote bags or clutch purses, where quick access is key. Unlike clasps, they’re discreet, letting the leather’s texture take center stage. When explaining how are leather bags made, we note that magnetic snaps are embedded between layers of leather to avoid damaging the material.

O-Rings are circular hardware pieces that work with D-Rings to attach straps or accessories. They add flexibility, allowing straps to rotate, and are often used in backpacks or gym bags. In custom designs, O-Rings can be matched to zippers or clasps for a cohesive look.

At our leather custom production facility, we know that great leather bags are built from the inside out—and hardware is the unsung hero. Whether you’re designing a luxury handbag or a practical backpack, every hardware choice impacts the bag’s durability, functionality, and style. For clients curious about how are leather bags made, explaining hardware selection helps them appreciate the craftsmanship behind their custom piece.

Ultimately, bag hardware types are more than just components—they’re tools that turn leather into a functional work of art. By choosing the right zippers, clasps, D-Rings, and auxiliary hardware, you can create custom leather bags that stand out in a crowded market and exceed your clients’ expectations.