Designing a leather bag for OEM/ODM projects demands a seamless blend of creative vision and manufacturing practicality. Grasping how to design a leather bag—starting from a simple sketch to crafting a physical sample—is vital for meeting client expectations and laying a solid foundation for subsequent production. Below is a detailed breakdown of the factory sample production process, covering every key stage.

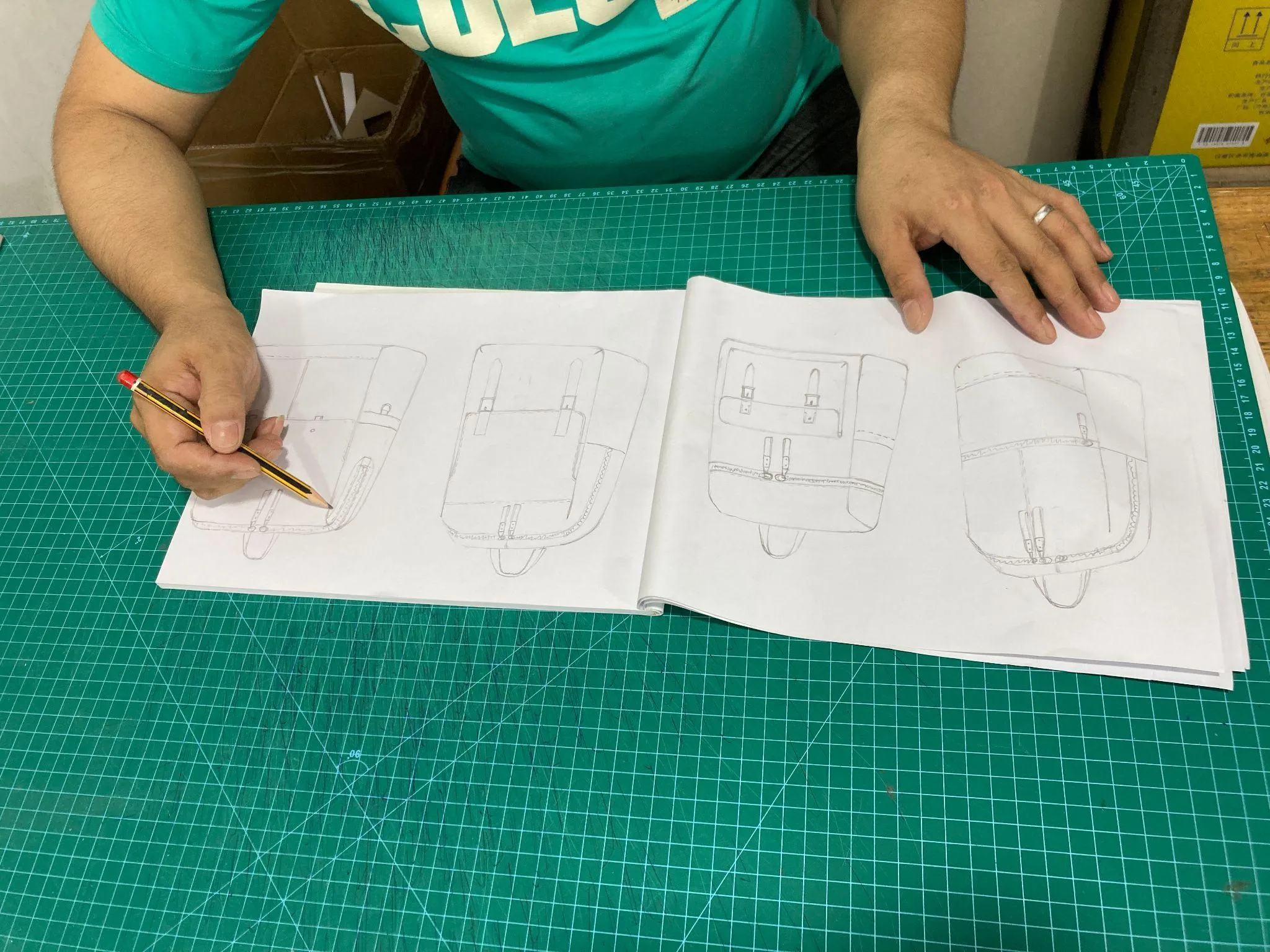

The initial step in how to design a leather bag is turning abstract concepts and client requirements into concrete sketches. This phase sets the direction for the entire design, so precision and alignment with client needs are paramount.

Every successful leather bag design starts with a deep understanding of the client’s demands. When figuring out how to design a leather bag, begin by collecting detailed information: the bag’s intended use (e.g., daily commute, travel), target demographic (e.g., young professionals, fashion enthusiasts), functional features (e.g., multiple compartments, waterproof linings), and aesthetic preferences (e.g., minimalist, retro). Use traditional tools like pencils and sketchpads or digital tools like Procreate to draft rough outlines. For example, if a client needs a travel-friendly backpack, sketches should emphasize spacious main compartments and secure laptop pockets. This stage of how to design a leather bag ensures that the design aligns with the client’s core needs from the very start.

Once the initial hand-drawn sketches get client approval, the next step in how to design a leather bag is digitizing and refining them. Employ professional design software such as Adobe Illustrator to create vector graphics, which offer high precision and easy modification. Add specific dimensions, like the bag’s height (e.g., 30cm for a small crossbody bag) and strap length (e.g., 120cm for an adjustable tote strap), to ensure manufacturability. Refine tiny details, including stitching styles (e.g., double stitching for durability) and hardware positions (e.g., zipper placement on the top of a clutch). This digital refinement in how to design a leather bag helps eliminate ambiguities and provides a clear reference for the subsequent production stages.

Choosing the right materials is a critical part of how to design a leather bag, as it directly impacts the bag’s durability, appearance, and cost. For OEM/ODM projects, material selection must also consider mass production feasibility.

When exploring how to design a leather bag, the choice of leather is fundamental. Common options include full-grain leather (known for its durability and natural texture, suitable for high-end bags), top-grain leather (smoother and more affordable, ideal for mid-range products), and bonded leather (cost-effective, used for budget-friendly designs). For custom leather bags with logo, full-grain or top-grain leather is often preferred, as logos embossed or printed on these leathers have a more premium look. Test the leather’s flexibility and wear resistance—for instance, a foldable leather pouch requires softer leather, while a structured briefcase needs stiffer leather. This careful evaluation in how to design a leather bag ensures the material matches both the design’s aesthetic and functional goals.

Hardware and accessories play a key role in enhancing the bag’s functionality and style, so they are an essential part of how to design a leather bag. Select components like zippers (metal zippers for a luxurious feel, nylon zippers for lightweight bags), buckles (brass buckles for retro designs, stainless steel buckles for modern styles), and handles (leather handles for consistency, chain handles for elegance). Ensure the hardware’s color and size coordinate with the leather—for example, a small mini bag should use delicate 5mm zippers instead of bulky 10mm ones. This matching process in how to design a leather bag elevates the overall quality and visual appeal of the sample.

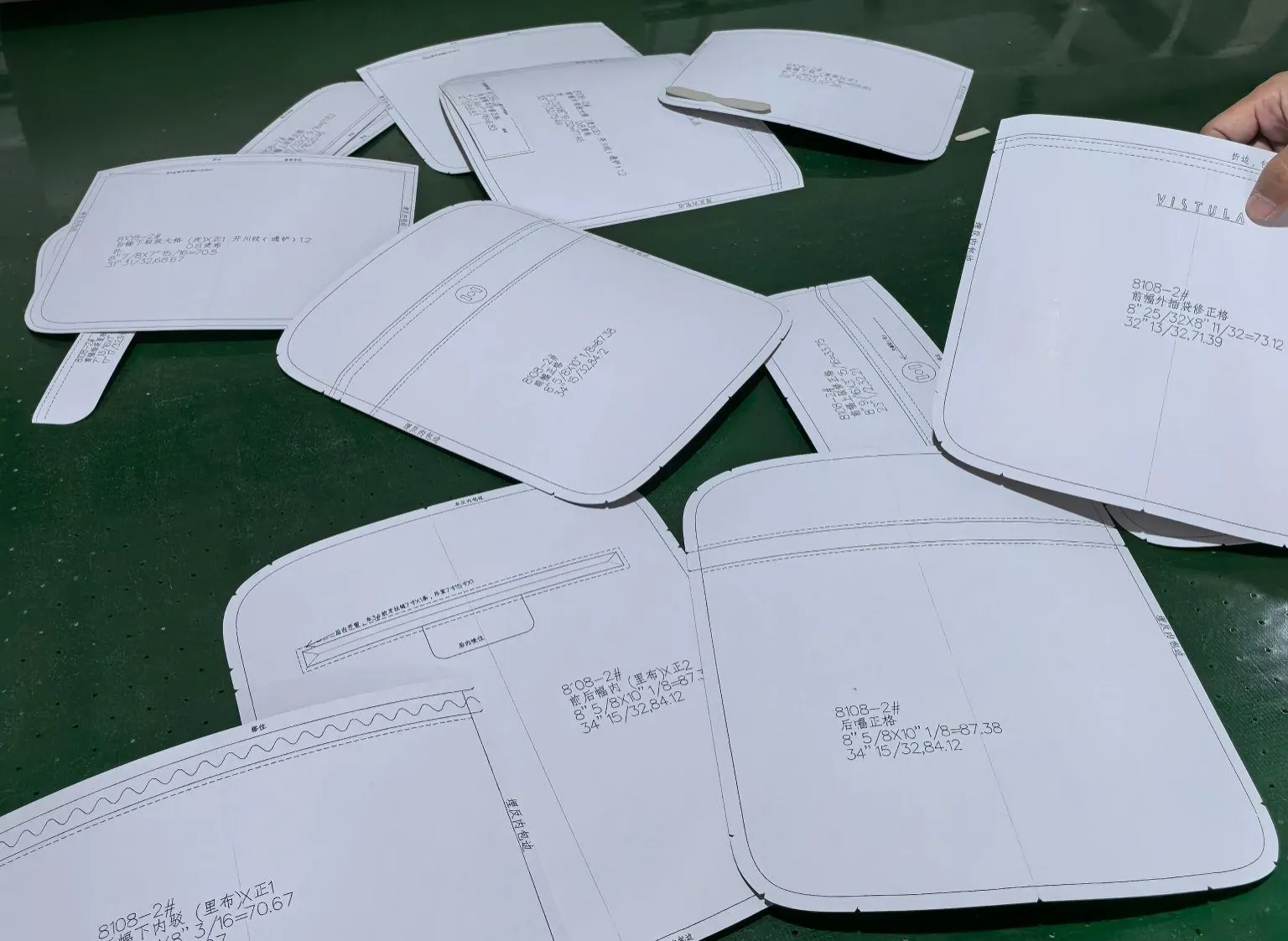

Pattern making is a bridge between design and production in how to design a leather bag. Accurate patterns ensure the leather pieces fit together perfectly during sewing.

The first step in pattern making for how to design a leather bag is creating 2D paper patterns based on the digital design. Factory pattern makers use the design’s dimensions to draft each piece, such as the front panel, back panel, and pocket pieces. Add seam allowances (usually 1-1.5cm) to each pattern to account for sewing. Label each pattern piece clearly, indicating the direction of the leather grain—since leather’s grain affects its strength and appearance, all pieces must be cut along the same grain direction. This precise drafting in how to design a leather bag prevents errors during the cutting stage.

Before cutting the actual leather, make 3D mock-ups using cheap materials like canvas or synthetic leather to test the patterns. This step in how to design a leather bag helps identify potential issues early. Assemble the mock-up by sewing the canvas pieces according to the patterns, then check the bag’s shape, size, and functionality. For example, test if the bag’s opening is large enough for easy access or if the strap’s length is comfortable for carrying. Adjust the patterns based on the mock-up’s performance—if the bag is too slouchy, add interfacing to the pattern pieces. This validation in how to design a leather bag saves time and reduces material waste.

Prototype sewing is the stage where the leather bag starts to take shape, marking a key milestone in how to design a leather bag for OEM/ODM projects.

Proper preparation is essential before sewing the prototype. In how to design a leather bag, this includes cutting the leather according to the final patterns using sharp leather shears to avoid fraying. Mark stitching lines and hardware holes on the leather with a leather marker—these marks guide the sewing process. Prepare the hardware by pre-drilling holes if needed, and pre-treat the leather edges with edge paint to prevent unravelling. For custom leather bags with logo, this is also the time to emboss or print the logo on the leather pieces. This preparation in how to design a leather bag ensures a smooth sewing process.

Sewing the prototype requires skill and attention to detail, which are crucial in how to design a leather bag. Use a heavy-duty sewing machine equipped with leather needles to stitch the leather pieces. Start with the internal components, such as pockets and linings, then move to the external structure, like attaching the front and back panels. Reinforce critical areas, such as strap attachments, with double stitching or rivets to enhance durability. During sewing, regularly check the stitching tension to ensure even and tight stitches. This careful sewing in how to design a leather bag results in a high-quality prototype that reflects the design’s intended look and functionality.

Testing and revising the sample is the final stage in how to design a leather bag before it’s approved for custom leather bag production.

Thorough testing is necessary to evaluate the sample’s performance. When considering how to design a leather bag, test its functionality by simulating real-life use: load the bag with typical items (e.g., a laptop, wallet, and phone) to check its weight-bearing capacity, zip and unzip the zippers repeatedly to ensure smooth operation, and wear the bag for a period to assess comfort. Evaluate the aesthetics by checking for consistent stitching, aligned hardware, and a smooth leather surface. For custom leather bags with logo, verify that the logo is clear, correctly positioned, and matches the client’s specifications. This testing in how to design a leather bag ensures the sample meets all quality standards.

After testing, share the sample and test results with the client to gather feedback. This step in how to design a leather bag is iterative—address any client concerns, such as adjusting the strap length, resizing a pocket, or changing the leather color. Make the necessary revisions to the prototype, then re-test to confirm the changes are effective. For example, if the client finds the bag’s handle too thin, replace it with a thicker leather handle. This revision process in how to design a leather bag ensures the final sample fully meets the client’s expectations and is ready for custom leather bag production.

In conclusion, how to design a leather bag from sketch to sample for OEM/ODM projects is a systematic process that requires careful planning, precise execution, and continuous iteration. By following the stages of sketch development, material selection, pattern making, prototype sewing, and sample testing & revision, and incorporating elements like custom leather bags with logo, you can create high-quality leather bag samples that lay the groundwork for successful custom leather bag production.