In the competitive world of fashion accessories, leather bags stand out for their durability, elegance, and timeless appeal. At our core, we believe that exceptional quality is non-negotiable, which is why our leather bag quality assurance process is the backbone of everything we do. From the moment raw materials arrive at our facility to the final check before shipment, every step is meticulously designed to ensure that each leather bag meets our uncompromising standards. As a leading leather bag factory in China with years of expertise, we take pride in transparency, allowing our customers to understand the care and precision that go into crafting each piece.

The journey of leather bag quality assurance begins long before production starts—with the careful selection and inspection of raw materials. We firmly believe that superior products can only come from superior inputs, which is why our raw material inspection process is rigorous and comprehensive.

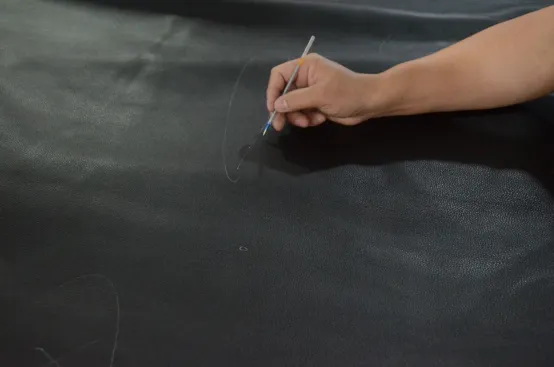

Leather is the soul of any leather bag, so we source only from trusted tanneries that share our commitment to quality and sustainability. Each batch of leather undergoes a series of tests to ensure it meets our standards. Our quality control (QC) team checks for thickness consistency, grain uniformity, and flexibility. We reject any leather with excessive blemishes, uneven coloring, or signs of poor tanning, as these flaws would compromise the final product’s durability and appearance. This strict initial screening is a critical part of our leather bag quality assurance, ensuring that only the finest leather moves forward to production.

Beyond leather, other materials such as threads, linings, and adhesives play a vital role in a bag’s performance. Our leather bag quality assurance process extends to these components as well. We test threads for tensile strength to ensure they can withstand daily use without fraying. Linings are inspected for durability, breathability, and colorfastness to prevent staining or tearing over time. Even adhesives undergo scrutiny—we use only high-quality, non-toxic options that provide strong bonding without damaging the leather. By leaving no stone unturned in raw material inspection, we lay a solid foundation for exceptional leather bags.

Once raw materials pass inspection, they move to the production floor, where our leather bag quality assurance process continues with meticulous in-line checks. Our skilled craftsmen work in tandem with QC inspectors to ensure that every stage of production adheres to our standards.

Stitching is both a functional and aesthetic element of leather bags, and our leather bag quality assurance process places great emphasis on its perfection. Our QC team monitors stitching in real-time, checking for consistent stitch length, even tension, and secure knotting. We specify a minimum number of stitches per inch to guarantee strength—too few stitches would weaken the structure, while too many could create unnecessary stress on the leather. Inspectors use magnifying tools to spot skipped stitches, loose threads, or uneven spacing, ensuring that each seam is strong enough to withstand years of use. This attention to detail during stitching is a testament to our dedication to leather bag quality assurance.

Hardware components such as zippers, buckles, rivets, and clasps are essential for a bag’s functionality and style. Our leather bag quality assurance process includes rigorous testing of these parts to ensure they meet our standards. Zippers are tested for smooth operation, with inspectors opening and closing them dozens of times to check for jamming or breakage. Buckles and clasps are evaluated for strength—we test their ability to withstand repeated use without bending or breaking. Even the plating on metal hardware is inspected for uniformity and resistance to corrosion, ensuring that it retains its shine over time. By maintaining strict standards for hardware, we ensure that every aspect of the bag contributes to its overall quality.

Before any leather bag leaves our facility, it undergoes a comprehensive final inspection—the last checkpoint in our leather bag quality assurance process. This stage is designed to catch any imperfections that may have slipped through earlier checks and to confirm that the finished product meets all our specifications.

Our final inspection protocol leaves no detail unexamined. Inspectors start by assessing the bag’s overall appearance, checking for consistent coloring, smooth edges, and proper alignment of panels. They then test functionality: zippers must glide effortlessly, straps must be securely attached, and pockets must open and close properly. We also conduct durability tests, such as gently pulling seams and hardware to ensure they hold firm. For custom leather bag production, this stage includes additional checks to verify that all customizations—whether embossing, unique designs, or specific dimensions—are executed precisely as requested. This tailored approach ensures that even custom orders meet our rigorous leather bag quality assurance standards.

Even after confirming the bag’s quality, our leather bag quality assurance process extends to packaging. We ensure that each bag is wrapped in protective materials to prevent scratches or damage during shipping. Labels and tags are checked for accuracy, ensuring that customers receive clear information about care instructions and product details. This final step ensures that the quality we’ve worked so hard to achieve is preserved until the bag reaches the customer’s hands.

At our leather bag factory in China, leather bag quality assurance is more than a process—it’s a promise. From selecting premium materials to conducting meticulous checks at every production stage, we are committed to delivering leather bags that combine durability, beauty, and functionality. Whether you’re purchasing a standard design or investing in custom leather bag production, you can trust that every bag has undergone our rigorous quality assurance process. We believe that transparency in our processes builds trust, and we’re proud to share the care and precision that go into crafting each leather bag. When you choose our leather bags, you’re choosing a product built to last—backed by a quality assurance process that never compromises.